Improved data quality and centralized product data management with inriver PIM

Koninklijke Paardekooper Group operates worldwide as the packaging specialist for the food and non-food industry. The family business has existed for more than 100 years and for this reason is entitled to bear the designation 'Koninklijk'. The innovative organizations and brands within this group set an example when it comes to sustainable packaging and production.

Need for a PIM system

Within Paardekooper, the various divisions were working with their own ERP systems, which caused duplication of effort and inefficiency. Products often had to be entered several times in different systems. With an assortment of over 80,000 products, this is a time-consuming and error-prone job. This is why Paardekooper felt the need for a central solution: one place where data is managed and enriched in an efficient and structured way. Time to streamline this process. This requires a solid IT foundation of which the implementation of a PIM system is an essential part.

Step 1: the PIM selection process

A successful PIM project starts with thorough preparation. That is why XSARUS PIM Masters started with a selection process, in which Paardekooper's issue was broadly examined and various PIM packages were extensively compared. Functional requirements in terms of data modeling, data quality, multilingualism and channels were analyzed to arrive at the best fit.

At the end of this analysis phase, inriver PIM proved to be the best fit for Paardekooper's requirements.

Step 2: the PIM implementation

The real work could begin, time for the implementation of the inriver PIM system. Everything came together in this phase: from data modeling and integrations to streamlining Paardekooper's internal processes.

One powerful integration

The PIM Masters got to work integrating Boomi. This is a user-friendly iPaas solution that acts as middleware. As a result, Paardekooper's new IT landscape is seamlessly connected to inriver PIM and all data is distributed to the right channels through one powerful integration.

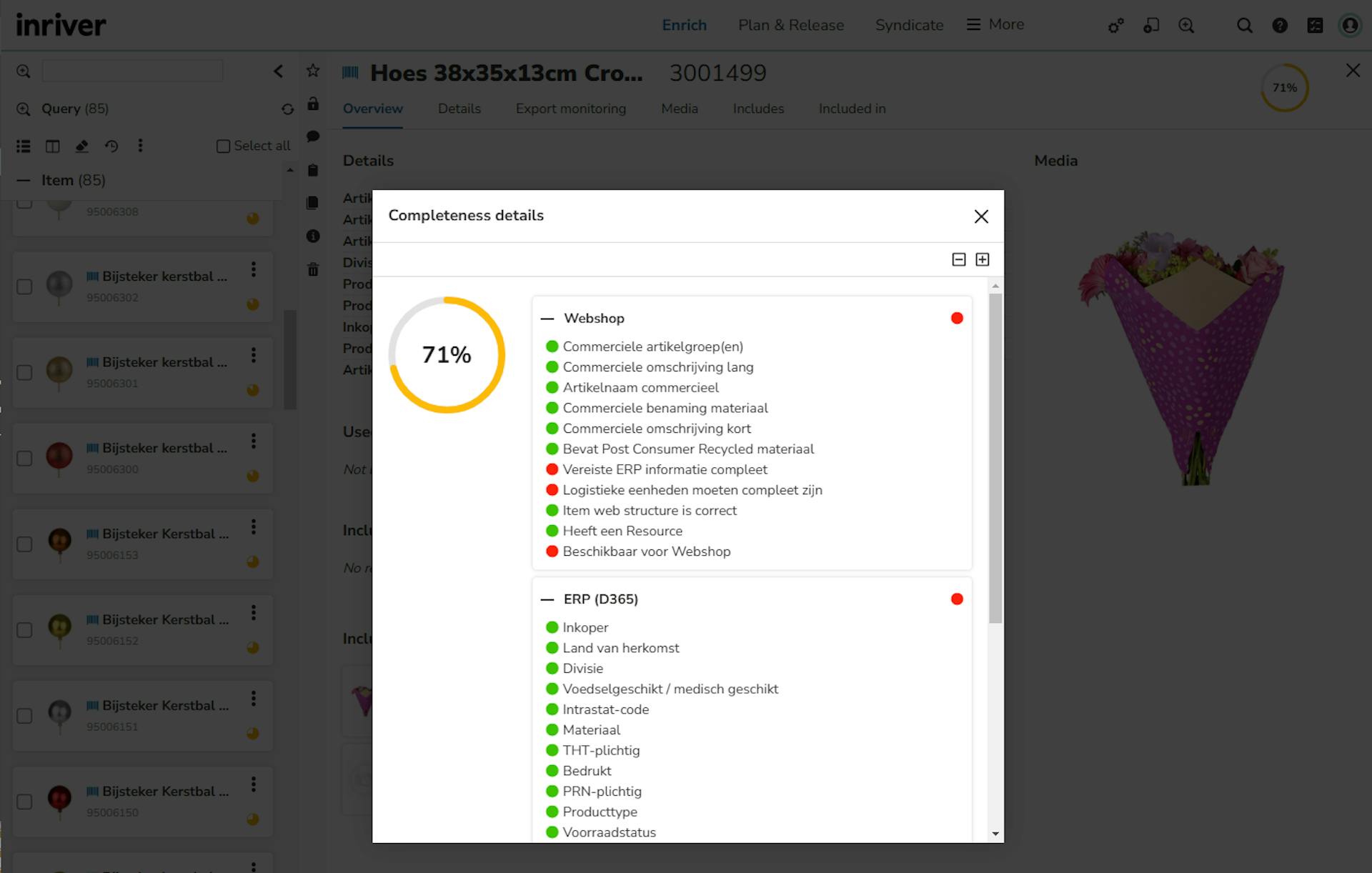

A boost for data quality

Thanks to the implementation of inriver PIM, the quality of product information is easy to monitor. Products are forwarded to the ERP system and the web shop only when the data quality has reached the right level. This ensures accurate product data, which is essential for good online presentation and sales. This layering of data quality was a key point for Paardekooper to improve their performance, and inriver fully complies.

Clear roles and rights

Different departments within Paardekooper, such as e-commerce, product management, sales, marketing and purchasing, will be working with the PIM system. It is therefore important that the right people have access to the right data. Inriver makes it easy to manage roles and rights so that everyone can work efficiently with the information that is relevant to them. In addition, the system offers plenty of opportunities to optimize workflows, further improving day-to-day processes.

Pack, unpack, but above all tackle

Cooperation during the project

Paardekooper's mindset proved to be an excellent match with that of XSARUS PIM Masters. The intensive cooperation, with regular physical collaboration on site, ensured that the implementation of the PIM system, including training, went according to plan.

Result

Paardekooper not only switched to a PIM system, but also renewed their entire IT foundation. From separate ERP systems to one central ERP, a new CRM system and the implementation of the PIM system: a complex and far-reaching change. This new technical foundation has successfully gone live at the first division. A major milestone has been reached. With inriver PIM, Paardekooper now has a solution that ensures data quality and guarantees consistency across all channels and languages.